Nitrile Butadiene Rubber

Nitrile is the most commonly used elastomer in the seal industry. Nitrile is a copolymer of two monomers: acrylonitrile (ACN) and butadiene. The properties of these rubber compounds are determined by its ACN content, which is broken down into three classifications:

- High nitrile >45% ACN content,

- Medium nitrile 30-45% ACN content,

- Low nitrile <30% ACN content.

The higher the ACN content, the better its resistance to hydrocarbon oils. The lower the ACN content the better its flexibility in low temperature applications. Medium nitrile is, therefore, most widely specified due to its good overall balance in most applications. Typically, nitriles can be compounded to work over a temperature range of –35°C to +120°C and are superior to most elastomers in regard to compression set, tear and abrasion resistance.

How it’s produced

Nitrile is produced by emulsifying butadiene and acrylonitrile together in water, then polymerizing the result, which converts the single unit molecules of the new combined material into larger molecules with multiple units. The end product can have from 15% to 50% acrylonitrile content, depending on the characteristics the manufacturer wants the rubber to have.

Applications

Automotive Industry

- Gaskets

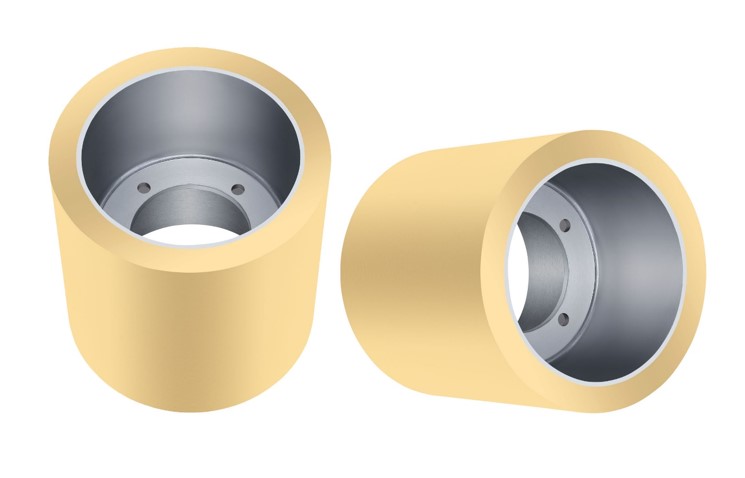

- Seals

- O-rings

- Carburetor and fuel pump diaphragms

- Fuel systems

- Hydraulic hoses

- Tubing

Bowling Industry

- Bowling pin setters

- Roller bumpers

- Anything that comes into direct contact with lane oil

Oil & Gas Industry

- Seals

- Tubing

- Molded shapes

- Rubber-to-metal bonded components

- Connectors

- (BOP) Blowout preventers

- Stripper rubber

- Rotating heads

Properties

- Nitrile Rubber belongs to the family of unsaturated copolymers of acrylonitrile and butadiene.

- The physical and chemical properties of nitrile rubber vary depending on the polymer’s composition of acrylonitrile.

- Different grades are available for this rubber. The higher the acrylonitrile content within the polymer, the higher the oil resistance.

- It can withstand a range of temperatures.

- It has inferior strength and flexibility, compared to natural rubber.

- Nitrile rubber is also resistant to aliphatic hydrocarbons.

- It is less resistant to ozone, aromatic hydrocarbons, ketones, esters and aldehydes.

- It has high resilience and high wear resistance but only moderate strength.

- It has limited weathering resistance.

- It can generally be used down to about -30 degree celcius , but special grades can also operate at lower temperatures.

Advantages

- Excellent abrasion resistance.

- Good rebound.

- Good tear resistance.

- Good non-polar solvent resistance.

- Good water resistance.

- Good oil resistance.

- Cheaper than fluoroelastomers

Disadvantages

- Poor ozone, sunlight, and weather resistance.

- Limited high temperature resistance.

- Poor flame resistance.

Technical Data Sheet

Tulsiram Hanumanbagas Gilada (THG), is a leading trade house for Synthetic Rubbers and Rubber Chemicals. Established and Lead by Mr Ramakant Gilada 3 decades ago at Hyderabad and later expanded to all over South India.

Contact Us

- thghyd@gmail.com

- +91 7893883141

Copyright © 2024 Tulsiram HanumanBagas Gilada. All Rights Reserved.